Thermal Protector

Thermal Protector( BW series ) and Current Thermal Protector( KI66/167 series )

Thermal protector( BW series )

Main Features:

- Small size

- Easy to install

- High-sensitive bimetal

- Fast reaction

- Low resistance

- Safe

- Vacuum coating

BW series temperature protector consists of round shape high sensitive bimetallic element, movable contact-head, static contact-piece, soleplate, outer case, thermal resistant lead and so on. When operation, the bimetal element is in free stage and movable contact head and static contact-piece are closed and the circuit is on. When the electric appliance is in operation and produce heat cause by some trouble and temperature is raise to the rated action temperature of the product. The bimetal element produce inner stress and act quickly and push the movable contact-head and make the contact point off and the power supply is turn off and the electric appliance stop. In this way the thermal protection is made. When the temperature of electric appliance to be protected is drop to the rated reset temperature, the bimetal element will restore to its primary stage and contact point is closed. The product has many advantages such as small is resister, quick response in temperature, and in action, safe and reliable, compact in size, etc.

1、Usage

thermal protector possess the benifits of miniature size、shell insulation、sensitive in action、long life etc.Widely used in electric power points、electrical appliances、fluorescent ballasts、transformers、automobile motor、integrated circuit and general electric equipment of dual hot flow protection function

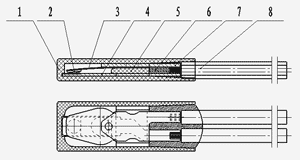

2、Appearance and structure:

| NO | Name of parts | Name of material | NO | Name of parts | Name of material |

| 1 | shell | PBT CRN7030 | 5 | Fixed block pieces | PBT CRN7030 |

| 2 | Dynamic contact | AgNi/BZn | 6 | epoxy | 9002A |

| 3 | Dual metal | 30R | 7 | Dynamic contact pieces | BZn |

| 4 | Static contact | AgNi10/BZn | 8 | Lead wire | 22# 3266 |

Note: 200 ° c, heat-resistant material shell combustion levelv

3、Property

3.1 Voted curren

4A/DC12V、3A/DC24V、3A/AC115V、2A/AC250V.

3.2 Disconnect temperature: 30 ° ~ 155 ~ 20 °c ,reset temperature 110 degrees Celsius (see drawing).

3.3: Ant-tension test: Product test pins should with no fault, sliding out when bearing >=20N.

3.4 Insulation voltage:

a. Products in the lead when disconnect between AC660V shall withstand, 1min without breakdown

flashover phenomenon;

b. Product leads and insulated shell, between AC1800V can withstand 1S without breakdown flashover

phenomenon.

3.5 Insulation resistance: under normal conditions, fuses and insulation shell insulation resistance in 100M Ω above. (used forDC500V meter)

3.6 Contact resistance: Pproduct contact resistance shall not be more than 50mΩ。

3.7 High temperature resistant test: The action temperature the should keep in 96h in temperature of 50 ° c rated movements in air environment.

3.8 Low temperature resistance test: product should keep in 96h when in air environment - 40 ° c

3.9 Ant-vibration test: thermal protectors shall withstand amplitude, frequency changing 1.5 mm 10 ~ 55Hz, scanning change cycle 3-5 times/min, vibration directionX,Y,Z, in each direction, each successive 2h vibration.

3.10 Drop test: products high free fall from 0.7 m.

3.11 Compression test: products shall stand 1min in100N static pressure.

3.7,3.8,3.9,3.10,3.11should meet the following requirements:

a. Disconnect temperature charges in the inditial value should be within +7℃

b. contact resistance should be below 100mΩ;

c. appearance should be no bovious deformation;

d.wires should without cracking damage.

4、Life

Products in the rated voltage, current, power factor for 0.7 conditions, plus 6,000 times that the action of

heat, should satisfy as below:

a. Disconnect temperature changes in the initial value should be within + 5 ° c,

b. Ccontact resistance should be belowin100mΩ continue experiment in 10000times after action。

5、Othere items:

5.1Disconnect the temperature detection 5.1 heating rate should be controlled for 1 ° c / 1min, Use process

cannot bear strong impact and stress.

5.2 Models of specifications

TB02B——production specifications

XXX℃——voted disconnect temperature

6、This standard should separtely conclude when not related to other matters or customer

requirements.

| NO. | OPEN | CLOSE | NO. | OPEN | CLOSE |

| 30 | 30±3℃ | ≥20℃ | 95 | 95±5℃ | 70±15℃ |

| 35 | 35±3.5℃ | ≥25℃ | 100 | 100±5℃ | 70±15℃ |

| 40 | 40±4℃ | ≥30℃ | 105 | 105±5℃ | 75±15℃ |

| 45 | 45±4.5℃ | ≥33℃ | 110 | 110±5℃ | 75±15℃ |

| 50 | 50±5℃ | ≥35℃ | 115 | 115±5℃ | 80±15℃ |

| 55 | 55±5℃ | 42±6℃ | 120 | 120±5℃ | 85±15℃ |

| 60 | 60±5℃ | 45±8℃ | 125 | 125±5℃ | 85±15℃ |

| 65 | 65±5℃ | 48±10℃ | 130 | 130±5℃ | 90±15℃ |

| 70 | 70±5℃ | 50±12℃ | 135 | 135±5℃ | 95±15℃ |

| 75 | 75±5℃ | 53±14℃ | 140 | 140±5℃ | 100±15℃ |

| 80 | 80±5℃ | 55±15℃ | 145 | 145±5℃ | 100±15℃ |

| 85 | 85±5℃ | 60±15℃ | 150 | 150±5℃ | 105±15℃ |

| 90 | 90±5℃ | 65±15℃ | 155 | 155±5℃ | 110±15℃ |